In the intricate world of modern industry, where precision and efficiency are paramount, the impact of Engineering Manufacturing Services cannot be overstated. These services form the backbone of production across various sectors, providing the expertise and technological prowess necessary to transform conceptual designs into tangible products that meet the demanding standards of todayÕs markets.

The Core of Engineering Manufacturing Services

Engineering Manufacturing Services offers a comprehensive suite of capabilities that include product development, manufacturing process improvement, tool design, and full-scale production. These services enable companies to not only build their products but to optimize every aspect of the manufacturing process. By integrating cutting-edge technologies and innovative methods, these services help businesses enhance productivity, reduce costs, and improve product quality.

Enhancing Efficiency and Productivity

The integration of modern manufacturing techniques such as automation, robotics, and computer-aided manufacturing has revolutionized production lines. This modern approach not only speeds up the manufacturing process but also improves the accuracy and consistency of the products. As a result, businesses can achieve higher output with lower operational costs, giving them a significant competitive edge in the global marketplace.

Innovation through Engineering Analysis Services

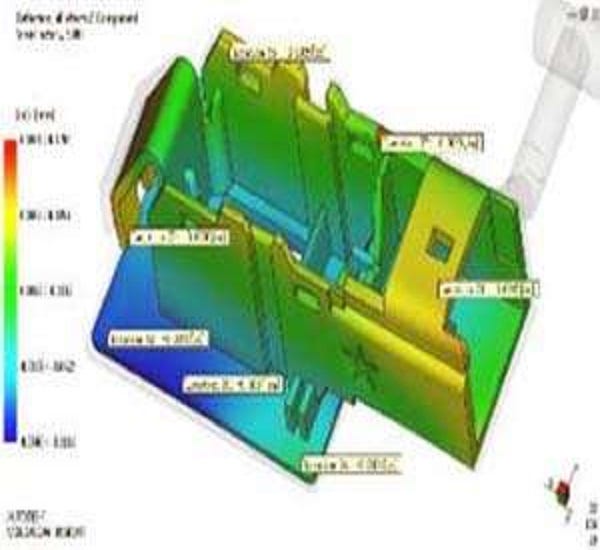

Diving deeper into the technical aspect, Engineering Analysis Services play a pivotal role in ensuring the viability and performance of engineering solutions. These services involve a variety of analyses, including structural, thermal, and fluid dynamics studies, which are crucial for assessing the sustainability and safety of designs before they are physically manufactured.

Sustainability and Customization

Today, there is a growing emphasis on sustainability within the manufacturing industry. Engineering Analysis Services contribute significantly to this endeavor by allowing companies to simulate and test how products will perform under real-world conditions without the need to physically create them. This not only saves materials but also reduces the waste associated with trial and error in product development. Furthermore, these services facilitate customization, enabling manufacturers to tailor products to specific customer needs without compromising on efficiency or increasing costs.

Conclusion

The seamless integration of Engineering Manufacturing Services and Engineering Analysis Services is crucial for the development of innovative, efficient, and sustainable manufacturing solutions. These services are instrumental in driving the progress of numerous industries by enhancing product quality, reducing time-to-market, and fostering innovation. For companies looking to harness the full potential of these advanced services, feamax.com offers expert guidance and cutting-edge solutions. As industries continue to evolve, the synergy between comprehensive manufacturing services and detailed analytical expertise will remain key to achieving new heights in industrial achievement.

Blog Source URL: - https://feamax1.blogspot.com/2024/10/shaping-future-with-advanced.html