In the quest to design products that are both innovative and reliable, engineers increasingly turn to advanced simulation techniques. Tools like Finite Element Analysis Consultants and Computational Fluid Dynamics Consulting have become essential in a multitude of industries, helping to predict product behavior under various conditions with unprecedented accuracy. This article explores the critical role these consultants play in driving engineering projects to successful completion while ensuring efficiency, safety, and performance.

Leveraging Finite Element Analysis Consultants

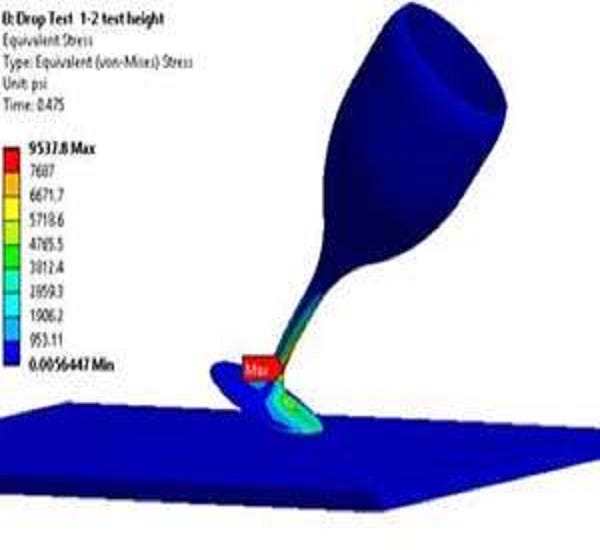

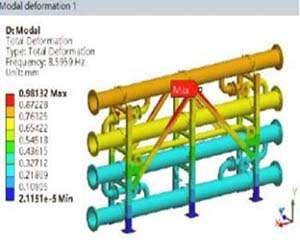

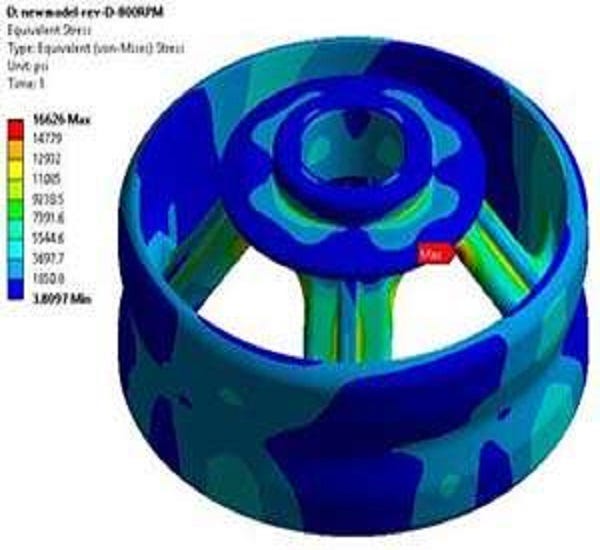

Finite Element Analysis Consultants specialize in using FEA tools to dissect complex engineering problems into manageable simulations. These consultants provide insights that help predict how product designs will react to physical forces, such as vibration, heat, and other environmental stresses. The knowledge and expertise of FEA consultants allow companies to diagnose potential problems early in the design process, optimizing designs to enhance durability and performance while reducing material costs and weight.

Enhancing Design Accuracy and Integrity

The ability to accurately simulate and analyze stress, fatigue, and heat transfer within components is invaluable. This not only enhances the structural integrity and durability of products but also ensures that they can withstand extreme conditions. Finite Element Analysis not only supports the design phase but also contributes to product innovation by allowing engineers to test new materials and shapes effectively before manufacturing begins.

Streamlining Product Development

Through detailed FEA simulations, companies can streamline their product development processes. This strategy lessens the requirement for actual prototypes, allowing for rapid iterations and refinements based on simulation results. By integrating these insights during the early stages of design, companies can significantly cut down on development time and cost.

Advancing with Computational Fluid Dynamics Consulting

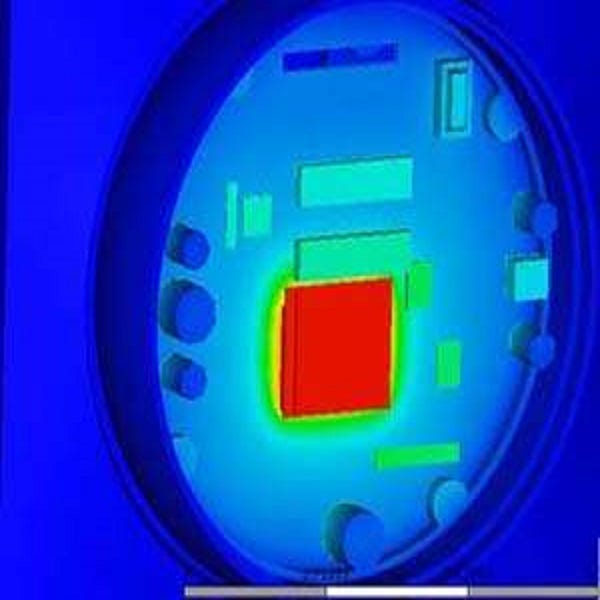

Computational Fluid Dynamics Consulting plays a pivotal role in optimizing processes that involve fluids, gases, and their interactions with various surfaces. These consultants apply CFD tools to simulate fluid flow, heat transfer, and related phenomena, providing critical data that can inform design decisions in automotive, aerospace, HVAC, and processing industries, among others.

Empowering Innovations with Fluid Dynamics

The expertise of CFD consultants is crucial for designing more efficient systems and components in sectors where fluid dynamics is a major concern. Their ability to predict complex fluid interactions and thermal management issues enables engineers to innovate with confidence, leading to safer, more efficient, and cost-effective products.

Conclusion

In summary, Finite Element Analysis Consultants and Computational Fluid Dynamics Consulting are at the heart of modern engineering, enabling the detailed study and optimization of complex designs. These consultants provide the tools and expertise necessary to navigate the challenges of modern engineering projects, ensuring that innovations not only meet design criteria but also exceed performance expectations. For further exploration of these advanced engineering services, FEAmax.com offers a comprehensive suite of resources and expert guidance. Harnessing these sophisticated simulation capabilities is crucial for any organization striving to lead in technology and innovation.

Blog Source Url:

https://feamax1.blogspot.com/2024/12/mastering-complexity-how-advanced.html