In the competitive landscape of modern industry, the transition from conceptual design to tangible product is pivotal. In this process, engineering design services are absolutely important since they help to close the gap between creative ideas and market-ready solutions. These services not only accelerate product development but also enhance the capability to meet and exceed market demands efficiently.

The Strategic Role of Engineering Design Services

The Engineering Design Services involve comprehensive planning, analysis, and creation of detailed designs using advanced technologies. This step is the first in transforming an idea into a feasible product. By enabling companies to conceive, simulate, and iterate designs with precision, these services ensure that every aspect of the product is optimized for functionality and manufacturability before it hits the production line.

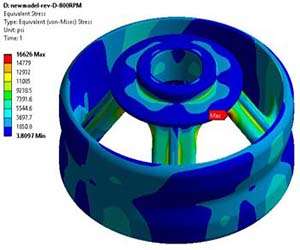

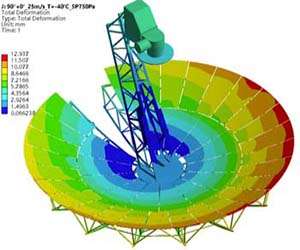

Optimizing Product Development with Advanced Design

Through the integration of state-of-the-art software and skilled expertise, Engineering Design Services allow for the creation of highly detailed and accurate models. These models are absolutely essential for seeing possible problems early in the development process, therefore lowering the risk and cost related with post-production modifications. Simulations and virtual testing refine products to ensure robustness and performance.

Transitioning to Engineering Manufacturing Services

As designs reach their final stages, the role of Engineering Manufacturing Services becomes pivotal, turning well-crafted designs into physical products. This phase involves selecting appropriate materials, methods, and technologies to produce parts and assemblies at scale. It ensures the efficient alignment of production processes with the specifications and tolerances established during the design phase.

Ensuring Quality and Efficiency in Production

The application of Engineering Manufacturing Services is essential for ensuring that production processes are both efficient and cost-effective. Utilizing cutting-edge manufacturing technologies and techniques, these services enable the mass production of components with high precision and minimal waste, crucial in industries where quality and adherence to safety standards are non-negotiable.

The Synergy of Design and Manufacturing in Engineering

The integration of Engineering Design Services with Engineering Manufacturing Services ensures a seamless transition from design to production, maintaining the integrity of the original design while adapting to practical manufacturing constraints. This synergy reduces the time-to-market and improves the overall competitiveness of the product.

Conclusion

The effective collaboration between Engineering Design Services and Engineering Manufacturing Services represents a comprehensive approach to product development. This partnership not only facilitates the efficient translation of ideas into products but also ensures that these products are innovative, reliable, and ready for a competitive market. For those seeking expert guidance and implementation in these areas, visiting feamax.com provides access to top-tier engineering solutions that can significantly enhance the trajectory of your projects from concept to creation.

Blog source URL :-

https://feamax1.blogspot.com/2024/08/from-concept-to-creation-unleashing.html