Imagine designing a high-speed train or a cooling system without knowing how air or liquid will move through it. ThatÕs where Computational Fluid Dynamics Consulting becomes essential. From predicting airflow over wings to optimizing ventilation systems, fluid flow simulations provide deep insight into performance, safety, and efficiency long before the first prototype is built.

Detailed Insight Drives Better Engineering

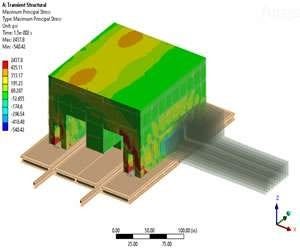

Precise calculations and real-time simulations are critical in understanding complex fluid behaviors. CFD Consulting Services allows engineers to visualize pressure points, turbulence, and velocity gradients within a system. This enables them to refine geometry, reduce drag, and enhance thermal management. Every insight leads to better designs that function effectively in real-world conditions across various industries.

Problem-Solving Through Advanced Simulation

Ignored, unanticipated fluid interactions might cause design failure. ThatÕs why Computational Fluid Dynamics Consulting plays a pivotal role in identifying and correcting these issues early. Whether the challenge involves mixing fluids in chemical reactors or optimizing HVAC airflow in large buildings, CFD provides the data needed to make informed, performance-driven decisions.

Optimizing Designs with Predictive Data

Effective engineering solutions depend heavily on prediction and testing. CFD Consulting Services utilizes sophisticated modeling tools that simulate various flow scenarios. These predictions help reduce reliance on costly physical testing and allow multiple design variations to be evaluated quickly. This approach increases efficiency, cuts development time, and improves product quality through early optimization.

Industries Benefiting from CFD Expertise

Applications for Computational Fluid Dynamics Consulting span aerospace, automotive, energy, electronics, and biomedical sectors. Engineers apply these simulations to study combustion systems, improve turbine efficiency, or design better drug delivery systems. Every project benefits from the predictive capabilities of CFD, making it a crucial element of modern engineering strategy and innovation.

Simulation Precision Leads to Innovation

Accurate modeling is the key to staying ahead in a competitive market. CFD Consulting Services provides the high-fidelity simulations necessary to fine-tune even the most complex systems. By understanding how fluids behave in confined or open environments, companies can minimize risk, enhance reliability, and deliver innovative solutions backed by solid data and technical insight.

Conclusion

Precision fluid modeling is no longer optionalÑitÕs essential for innovation, safety, and performance across every engineering discipline. Those seeking expert guidance in simulation and fluid behavior should explore the expertise at feamax.com. Combining powerful Computational Fluid Dynamics Consulting with reliable CFD Consulting Services equips engineers with the tools they need to design confidently, predict outcomes, and push boundaries in every technical project.

Blog Source Url:-

https://feamax1.blogspot.com/2025/05/simulate-and-optimize-with-expert-fluid.html