- SingaporeÕs construction and infrastructure development industry is on the rise, and aluminium extrusions are widely used since they are flexible, long-lasting and have a low weight. Let's explore the top 5 applications of aluminium extrusion Singapore across various construction segments:

1. Windows and Doors

Due to the superior strength-to-weight ratio of aluminium, one can build bigger designs of large windows and doors that can allow more natural light. Aluminium windows and doors are able to integrate well with modern architectural trends thanks to aluminium section minimalist profiles.

Leading aluminium suppliers in Singapore, such as Kian Huat Metal, offer a variety of window, door and curtain wall aluminium extrusion profiles.

Building Façades and Cladding

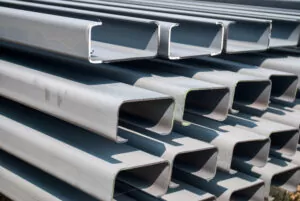

One of the most widely used aluminium cladding sheets and panels is employed mainly in building exteriors and façades. Aluminium claddings are one of the best in protecting structures subjected to severe weather conditions without sacrificing much structural strength because aluminium is a relatively light metal.

Design flexibility is another great advantage of texture-coated aluminium sheet Singapore claddings for builders and architects. In terms of maintenance, using aluminium cladding is hassle-free as the material does not rust or corrode. This allows the cost of repairs to be minimized throughout the life cycle of buildings.

3. Scaffolding

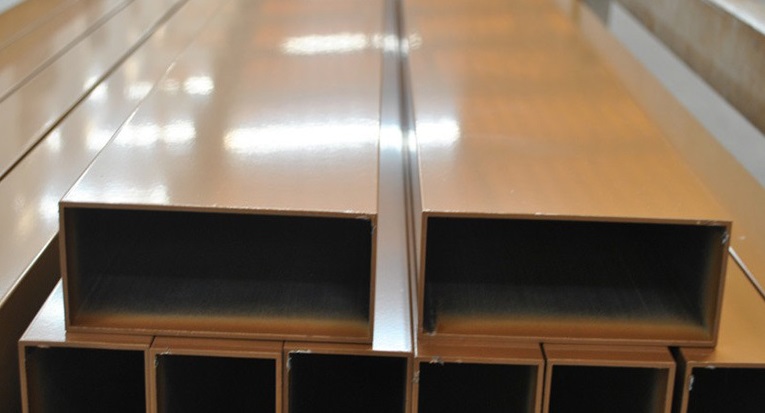

- Aluminium scaffolding offers numerous benefits and advantages compared to traditional steel scaffolding systems. Aluminium scaffolding provides strength and stability for load-bearing with an emphasis on portability with a much lighter design to allow much greater ease of installation.

It is the sections and profiles, such as aluminium beam Singapore, that offer flexible configurations to meet varying access requirements at the construction sites. Aluminium scaffolds are also corrosion resistant, hence minimizing maintenance and enhancing cost-effectiveness.

4. Interior Fittings

The versatility and aesthetics of aluminium extrusions make them the perfect choice for all kinds of interior fittings and building features. Aluminium sections can be easily machined and treated, allowing contractors great design freedom for customized interior elements.

Stainless steel fabrication Singapore specialists commonly use aluminium for bespoke items like partition panels, display frames, wall cladding and trim, flooring trims and lighting coves or pelmets integrated with concealed lighting. The modern, minimalist look and feel of aluminium contribute beautifully to commercial and residential interiors.

Furniture and Fixtures

The aluminium extrusion furniture provides functionality, style and durability. Aluminium extrusions allow meeting tables, chairs and display units, and storage solutions to have slim profiles due to the inherent strength of aluminum. Powder-coated aluminum furniture maintains its freshness over the years with little maintenance and is abrasion resistant.

Shops and malls also use custom metal fabrication Singapore services to produce point-of-sale displays, signboards, and decorative facades from aluminium extrusions. Ease of manufacture makes possible endless variants in innovative retail fixtures.

Conclusion

So there you have it - a brief overview of how aluminium extrusion in Singapore enables versatility, efficiency and creativity across the construction sector. Whether itÕs structural elements or elegant interiors, aluminium delivers on performance, quality and sustainability.

To access one of the widest inventories of aluminium extrusions in Singapore and custom aluminium profile fabrication services, connect with the specialists at Kian Huat Metal today.