The dimensions of hollow structural sections, which come in square, rectangular, and circular shapes, are referred to as hollow section sizes. These sizes accommodate different load-bearing capacities and structural designs, depending on the particular requirements of engineering and building projects. Hollow section size are versatile and durable in a variety of industrial contexts, delivering lightweight yet robust support for applications like machinery, building structures and bridges.

I beam size are the measurements of steel beams with an I form that are utilised in building projects. These dimensions fluctuate based on the project's particular specifications, such as span length and load-bearing capability. Common sizes range from modest residential buildings to substantial commercial and industrial structures, offering crucial stability and structural support in a variety of technical applications.

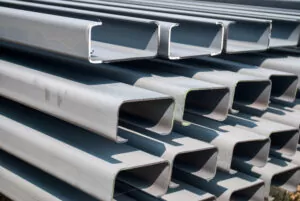

Lip channel are structural elements with a lip on one side and a U-shaped cross-section. They are also referred to as C channels or U channels. Lip channels are frequently used in manufacturing and construction to offer strength and support for a variety of uses, including reinforcing, bracing, and framing. They are crucial components of industrial equipment, machinery, and building frames because of their adaptability and simplicity of installation.

A metal perforated sheet with holes drilled through it at regular intervals is a versatile material. This perforated metal pattern is ideal for a variety of applications since it offers advantages such enhanced airflow, sound absorption, and visibility.

Common applications in the building, automotive, manufacturing, and architectural industries include screening, filtration, acoustic panels, decorative facades, and ventilation systems.

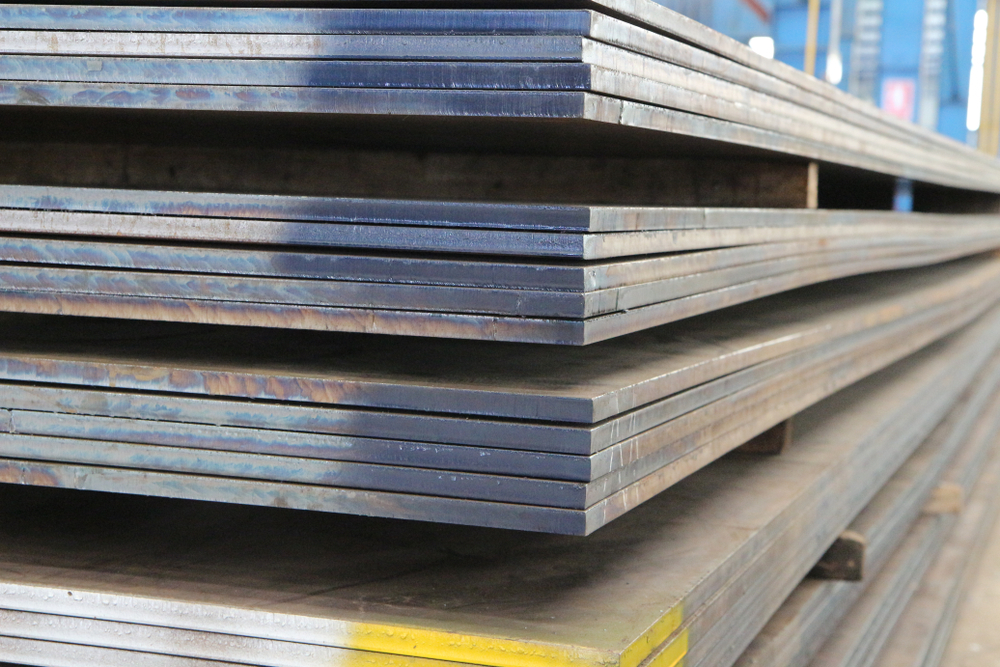

A flat sheet of metal, usually composed of steel, aluminium, or stainless steel, is called a metal plate. To accommodate a range of industrial and commercial uses, metal plates are available in a variety of thicknesses, widths, and shapes. For applications including structural support, cladding, flooring, signs, and equipment parts, they are utilised in the construction, manufacturing, automotive, aerospace, and other industries.

Stainless steel tubes are long-lasting, cylindrical hollow constructions composed of stainless steel, an alloy renowned for its resistance to corrosion. Because of their remarkable qualities, these tubes are widely employed in many different industries, including manufacturing, automotive, aerospace, and construction. High strength, superior mechanical qualities, and resistance to corrosive conditions and high temperatures are all features of stainless steel tubes. Heat exchangers, fluid transportation, pipe systems, and structural frames are examples of common applications. Stainless beam come in a variety of grades, diameters, and finishes, making them adaptable to a broad range of engineering and fabrication requirements. This ensures durability and dependability in a wide range of applications.