In the development of construction, engineering and infrastructure, the use of the right substances is important to ensure safety, efficiency and long -term performance. From powerful fees structural steel additives to accurate quality seamless pipe structures, each element makes a necessary position to bring architecture and commercial initiative into lifestyle. LetÕs explore the extensive range of products such as metallic grating, steel hollow section, and others which are key to trendy project fulfillment.

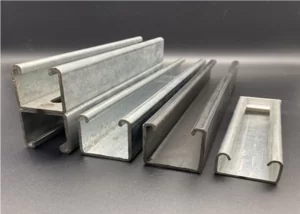

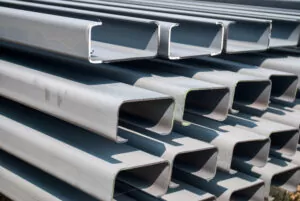

Structural Steel and Hollow Sections for Frameworks

When it comes to making a strong and stable disposition, construction steel remains the spine in maximum trade and industrial construction. It provides unmatched power and endurance, which is best for high -growing buildings, bridges, goddowns and industrial plants. Deformation and its resistance to adaptability to one of a type of design ensure that structural requirements are met without it coming to a chord.

The metal hollow section is one of the most flexible manufacturing additions, available in round, square, and square forms. These sections offer advanced electricity-to-weight ratios, making them best for frames, supports, and load-bearing applications. Their aesthetic attraction and lightweight nature also make them appropriate for architectural packages.

For introduced precision and consistency, the Square Hollow Section offers a smooth, symmetrical profile, commonly utilized in fencing, equipment, and structural fabrication. It permits for uniformity in layout and easier welding and becoming, reducing fabrication time and cost.

Safe Walkways and Platforms with Steel Grating

For commercial walkways, mezzanines, stair treads, and platforms, metal grating gives a safe and sturdy solution. Known for its excessive load-bearing capacity and anti-slip floor, it's miles often utilized in factories, refineries, and shipyards. Steel grating allow for drainage, ventilation, and visibility, making them perfect for excessive-visitors or risky areas.

Pipes and Beams for Industrial Applications

A reliable Pipe Supplier is essential for ensuring the steady availability of first-class piping answers across various programs. From plumbing and HVAC to gasoline and oil systems, reliable piping substances could make or smash a project. Working with a supplier that offers a huge style of pipes guarantees that you obtain the proper specs, cloth grades, and coatings as needed.

Among the most in-call for piping solutions is the Seamless Pipe, desired for its strength, uniformity, and resistance to excessive stress. Unlike welded pipes, seamless pipes are produced with out joints, lowering the threat of leaks and making them suitable for vital programs in oil and gas, energy plant life, and chemical processing.

Another key product utilized in huge-scale construction is the Metal Beam. Designed to support the load and long -lasting bridge, steel beams are important in both horizontal and vertical structural applications. They provide pressure, reduce the deflection and are usually used in highways, commercial buildings and industrial plants.

Conclusion

Selecting the appropriate metallic product is essential to the success of the project. Whether you need a corrosion-resistant Seamless Pipe, long lasting steel grating, or sturdy Structural Steel for production frameworks, having a reliable dealer ensures high-quality, protection, and timely transport. Build with self belief by way of choosing depended on answers like steel hole phase, Metal Beam, and Square Hollow SectionÑcrafted for overall performance and designed to ultimate.