An efficient workspace plays a vital role in industries dealing with sensitive electronic components. Even a minor electrostatic discharge can damage circuits, leading to costly repairs and downtime. To mitigate such risks, specialized furniture like an ESD workbench is essential. These workstations are designed to dissipate static electricity, ensuring a controlled environment for handling delicate electronics. Without proper precautions, electrostatic buildup can cause significant damage, making static-safe workstations a necessity in industries such as electronics manufacturing, laboratories, and assembly units.

The Importance of an ESD Workbench in Electronics Manufacturing

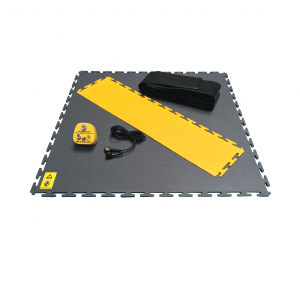

An ESD workbench provides a safe and organized space for professionals working with electrostatic-sensitive devices. Unlike standard tables, these workstations incorporate materials that effectively ground any static charge, preventing accidental discharge. Industries handling circuit boards, microchips, and semiconductors rely on these benches to ensure product quality and longevity. The integration of grounding mechanisms, conductive surfaces, and anti-static mats reduces the risk of electrostatic damage. Investing in a properly designed static-safe workstation enhances efficiency, minimizes losses, and protects valuable components from unseen electrical hazards.

Key Features to Consider in an ESD Workbench

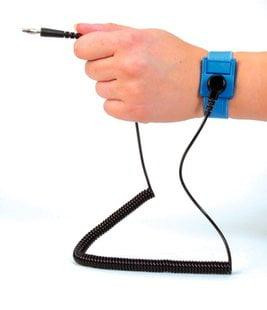

Selecting the right ESD workbench requires attention to specific features that enhance safety and functionality. Conductive or dissipative surfaces help neutralize charges, ensuring a controlled environment. Built-in grounding points provide additional protection by safely directing static away from sensitive components. Adjustable height options and ergonomic designs contribute to worker comfort, reducing strain during long hours of operation. Accessories like storage drawers, wrist strap connectors, and grounding cords further optimize performance. With the right specifications, these workstations create a static-free zone, making them indispensable in modern electronic workspaces.

How an ESD Bench Enhances Workplace Safety

A high-quality ESD bench goes beyond just providing a sturdy work surface. It actively prevents electrostatic discharge from affecting electronic devices, ensuring a safe and controlled environment. In industries where static-sensitive materials are handled daily, an effective grounding system is essential. Conductive elements built into these benches help dissipate electrical charges, eliminating risks associated with uncontrolled static buildup. By integrating advanced materials and grounding techniques, these benches protect expensive equipment, reduce operational losses, and maintain consistent product quality, making them a crucial investment for any facility handling delicate electronics.

Choosing the Best ESD Bench for Maximum Protection

Finding the right ESD bench involves considering factors such as surface material, grounding capacity, and ergonomic design. A well-constructed static-safe bench should include durable, non-conductive coatings to prevent accidental damage while providing effective charge dissipation. Additionally, modular designs allow customization based on specific workspace needs. Industries that prioritize electrostatic safety can significantly benefit from investing in high-performance benches that align with industry standards. For those seeking reliable solutions, Elcomltd.com offers a wide range of workbenches designed to meet the highest electrostatic protection requirements.