Plates made of metal, unlike other materials, tend to look more modern and sleeker. Due to their resistance to corrosion and abrasion, they find employment in construction contexts where sturdiness is prioritised over lightweight design. Because of its great strength-to-weight ratio, aluminium is the most popular metal plate. The architectural-grade aluminium plate comes in many different thicknesses, so even elaborate, outsized designs are feasible.

- Steel Plate

Steel plates are manufactured to exacting standards determined by the intended usage in the building industry. Steel plates for single-family homes vary from those needed for airports, sports arenas, and prefabricated constructions. Plates that are thicker and longer are required for roads, bridges, and railroad tracks. A wide variety of sizes and quality levels are available for Steel Supplier Singapore plates.

- Stainless Steel plate

When it comes to architecture, steel is utilised for building work that needs to fulfil its purpose and be durable and create style, and Stainless Steel Singapore is great for both goals. Stainless steel can make aesthetically pleasing additions to structures that would be prohibitively expensive if manufactured from any other material.

- Aluminium plate

Putting up buildings as efficiently as possible is only part of what modern buildings and construction entail. Aluminum, the current age's building material, became a major player in the construction business throughout the 20th century. Whether it's a brand-new construction or a renovation, Aluminium Supplier Singapore makes it feasible to realise any and all architectural ideas.

What is a flange?

A flange is a circular piece of metal with a larger hole in the centre and smaller bolt holes evenly spaced around the perimeter. Welding the huge opening and the pipe together. This pipe fitting has a tiny hole for mounting bolts and a flange for joining two other Pipe fittings. Flanges refer to the fastened and closed sections that join two planes at their edges.

A flange connection is a type of removable connection that consists of a collection of interlocking sealing structures, including flanges, gaskets, and bolts. It may join two pipes together invisibly and securely. To finish, bolt on the gasket. It's important to remember that the flanges' thickness varies with pressure, as do the bolts used to secure them. Bolt fastening is commonly used in pipelines and pressure vessels of mechanical equipment because of the ease with which it may be removed for maintenance.

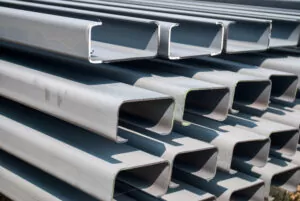

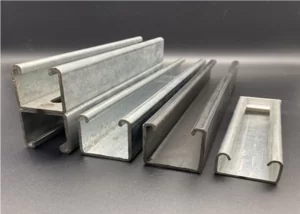

What's a purlin in construction?

Purlins are a popular term used in steel construction to refer to roof framing components that run parallel to the building eave and support the roof decking or sheeting. In most cases, purlins are made of steel. Z-shaped purlin are commonly utilised in Metal Building Systems to maintain flexural continuity between spans. There is a wide range of other uses for purlins as well.

Conclusion

These are the essential materials that every builder in the construction business needs since they are the components that go into the production of a wide variety of sections and pieces that go into the foundation of buildings and other structures, as well as parts of machinery. If you can recognise the various kinds of plates, you will be able to determine which one is the one that will work best for any given type of building job.