Door frame processing is an essential part of the door manufacturing industry, ensuring that each frame is crafted to precise specifications. Door frame processing equipment plays a critical role in the efficiency and accuracy of producing high-quality door frames. These machines automate the process, from cutting and shaping to assembling the final product, making them essential for large-scale production lines. With such equipment, manufacturers can achieve consistency, precision, and speed in meeting their production goals.

The Role of Door Cutting Machines in Manufacturing

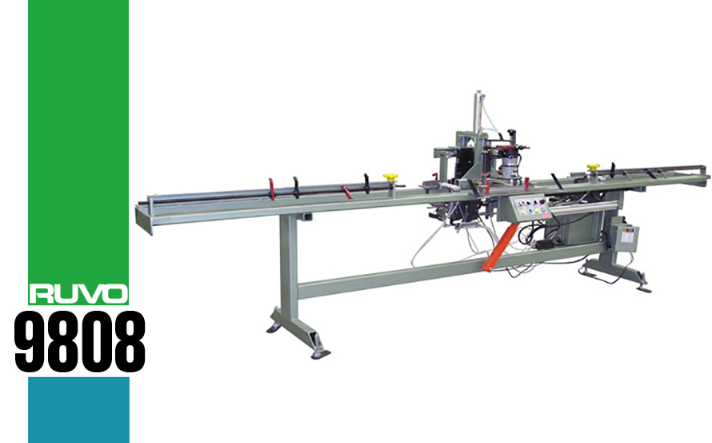

Door cutting machines are vital in the door manufacturing process, providing precise and clean cuts for frames and panels. These machines are specifically designed to handle materials like wood, metal, and composites, ensuring that each piece is cut to the exact dimensions required. The precision and speed of door cutting machines help reduce waste and minimize errors, ultimately improving production efficiency. Manufacturers rely on these machines to ensure that every door component fits perfectly during assembly.

Benefits of Using Door Frame Processing Equipment

The use of door frame processing equipment offers numerous benefits for manufacturers. These machines ensure that door frames are uniformly processed, which is crucial for maintaining the structural integrity of the door. Additionally, automated equipment allows manufacturers to scale up production without compromising quality. The ability to process frames with high precision also means that less material is wasted, reducing operational costs. With door frame processing equipment, manufacturers can meet high-demand orders while ensuring consistency and efficiency in their operations.

How Door Cutting Machines Improve Efficiency

Door cutting machines are designed to handle various tasks with precision, including making straight cuts, beveling edges, and cutting complex shapes. By automating these processes, manufacturers can achieve faster turnaround times and better results than with manual cutting methods. This automation ensures that every piece of the door is precisely cut, minimizing errors and reducing the need for rework. As a result, door cutting machines contribute significantly to improving overall operational efficiency and productivity in the manufacturing process.

Customization and Versatility of Door Frame Equipment

One of the key advantages of door frame processing equipment is its ability to customize frames according to specific project needs. These machines are designed to handle a variety of frame materials, including wood, steel, and aluminum. The versatility of the equipment allows manufacturers to adjust settings and configurations to create frames for different types of doors, whether for residential, commercial, or industrial use. This flexibility is essential for manufacturers who need to meet diverse customer requirements and deliver customized solutions.

Integrating Door Cutting Machines with Other Equipment

To maximize efficiency, door cutting machine are often integrated with other production equipment, such as door frame processing machines and assembly lines. This integration ensures that each step in the manufacturing process flows seamlessly, from the initial cutting to the final assembly. The ability to integrate various machines into a unified production system increases overall productivity and reduces downtime. By streamlining operations, manufacturers can improve output and meet production schedules more effectively, all while maintaining high standards of quality.

Conclusion

Door frame processing equipment and door cutting machines are essential tools for enhancing the door manufacturing process. These machines help manufacturers achieve high precision, efficiency, and flexibility, allowing them to meet customer demands and production goals. For more information on advanced door manufacturing solutions, visit Ruvodoormachines.com. Investing in these machines ensures that manufacturers can stay competitive in a fast-paced industry while producing high-quality, custom-made doors for various applications.